Category Archives: Blog

Buying Weld-On Carbide Teeth? Look Out for These Features

How to Keep Your Drilling Equipment Running with Pengo Auger Teeth?

Look For These Features in Coal Mining Drill Bits

Coal mining is one of the most demanding forms of drilling. That is due to the due the hard and rocky soil that you have to drill through to mine coal. Therefore, the kind of cutter tools that you need to for this job must be of the highest quality. If you are to buy coal mining drill bits, then there are key things that you need to consider. There are key features that make perfect drilling bits for coal mining. Here are just a few of them:

Quality of Materials Used

Even before you look for any other feature, it is important to start with the quality of the coal mining drill bits from the onset. The best way to assess the quality of drilling bits is by checking the material used for their construction. There a number of materials used for the drilling cutter tools construction but carbide and steel are the best options. Alloy steel is excellent for the body while tungsten carbide should make the tip. Tungsten carbide is one of the hardest metals in the industry, and that is why it recommended for the drilling tip.

Check The Quality of Joint

This is one of the features that most buyers forget but a very crucial one. As mentioned, coal mining drill bits have two parts- the carbide tip and steel body. The joining of the two metals requires a very string joint that can withstand demanding coal mining conditions. There are many technologies that are being used today, but brazing carbide is the best in the market. The technology produces one of the strongest joint for coal mining drill bits and other cutter tools used for demanding conditions.

Versatility

When it comes to coal mining, there are different types of rocky soils. Each of them could require different types of cutter tools to handle. However, you can make things easier by investing in coal mining drill bits that can be used on a vast range of drilling. That is what versatility of drilling bits is all about.

Extended Lifespan

Last but not least is the expected lifespan of the machine. You don’t want to invest in the kind of teeth that will last just a short period. Check the lifespan that the manufacturer has provided for the bits. Get the longest lifespan as they are likely to be of the best quality. That is how you get value for money.

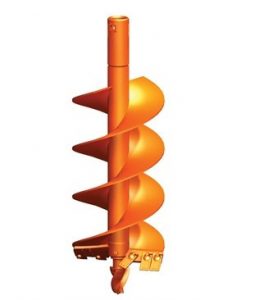

Check Out for These Technologies in Rock Auger Bits for Sale

Check Out for These Technologies in Rock Auger Bits for Sale

Investing in the drilling industry is one of the best decision you can make. Although you require a lot of investment to start, the return on investment is good. However, you must ensure that your drilling equipment is in good order always. Otherwise, machine performance and productivity will gradually reduce, causing a decline in your ROI.

However, manufacturers are making things better for you by producing more effective tools. They are now using several technologies to enhance tools’ performance. If you are looking for rock auger bits for sale, here are some of the technologies you need to consider.

Hardfacing

Hardfacing is one of the techniques being used by manufacturers to enhance the hardness of tools. The technique works by creating a coating of a harder metal on the tools to improve the hardness. In most cases, the inner metal is usually soft mostly used for giving tools their shape. The aim of using the technique is to enhance the performance and productivity of rock auger bits for sale. The technique also reduces the cost of rock auger bits for sale as the expensive metal only forms a coating. In most cases, chromium carbide is the material used for hard facing.

Brazing Tungsten Carbide

As we all know, rock auger bits for sale have two different parts. These two parts should be joined by a very strong joint, considering how demanding drilling rocky condition is. There are many techniques that are used to makes these joints, but brazing tungsten carbide is one of the best. It forms strong joints that can withstand the most demanding conditions. So if you are drilling in rock soils and your rock auger teeth are breaking, then you need to check the kind of joint used. While buying, invest in rock auger bits for sale joined with brazing tungsten carbide technique.

Hot and Cold Forging

Hot forging might be said to be the oldest technology for hardening metal. The technique has been used for years, and it continues to advance with technology. Today, it is also one of the widely used tool hardening techniques in the market. Forging is a process where the workpiece is heated or cooled to crystallization point. At this point, all you need is to deform the workpiece or the metal to assume the required of the auger bit. Hot or cold forged rock auger bits for sale offers extreme resistance to wear and abrasion and can withstand tough conditions.