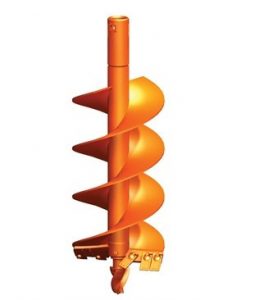

Benefits of Investing In Quality Rock Auger Teeth

Rock auger teeth or auger rock bits are some of the most specialized types of drilling tools for tough conditions. They are popular with foundation drilling due to their incredible features such as high wear resistance. They can withstand the toughest conditions, and that is why most operators prefer them. But quality is the key feature that is guiding you while shopping for these teeth. But what are key benefits of investing in quality rock auger teeth? Here are some of the benefits:

Constant Output

A constant output is guaranteed with quality teeth. You don’t want to have drilling parts that produce varying output now and then. In such cases, it is extremely difficult to plan your time and tell how long the project is likely to end. It will also be very difficult to tell the total cost of the projects of the project, especially on things such as the total cost of the labour & fuel. Therefore, make sure you have invested in the premium quality of auger rock bits to maintain a constant output.

Versatility and Compatibility

When it comes to rating versatility, rock auger teeth stand out from the rest. Apart from being design for the rocky soils such as drilling foundation, they can also be used for various soils such as abrasive types. Quality auger rock bits can also work extremely well on soft soil. When it comes to matters compatibility, these are the kind of teeth that can be used on a vast range of machine brands. So if you are operating some auger brands, you can be used these teeth on these machines.

Reduced cost of maintenance

Cost of maintenance is one of the challenges most operators struggle with. With the rock auger teeth, there is the likelihood of very high rate of wear and tear especially if you are doing foundation drilling. But if you have the best quality teeth where the tip is constructed from the highest grade of carbide and the body is made from premium steel, then you will experience a lower rate of wear and tear. That simply means lower cost of maintenance.

Extended Useful Life

Do you know that the condition of your auger rock bit determines the lifespan of your machine? Well, that is something that you always have in your mind while making a replacement. Therefore, by investing in quality rock auger teeth, you will enjoy your auger and your prime driver for an extended period of time.