Augers: A Key Component in the Future of Biomass

“Global biomass and waste power generation could grow to 270 gigawatts through the year 2030” – International Renewable Energy Agency

“Biomass will be the dominant form of renewable energy.” – David Minott at Int’l Biomass Conference and Expo 2013

So where does all this biomass come from ? How does it generate power? And, what role to augers play in the process ?

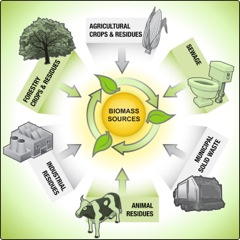

Biomass can be a wide variety of materials, but it is primarily biologically produced with the chief components being carbon, hydrogen and oxygen. The largest amount of biomass is wood. But biomass can also be used plastics, old tires, yard waste, wastewater treatment sludge, municipal solid waste or agricultural waste.

Pyrolysis is the thermal decomposition of organic and synthetic waste material at elevated temperatures in the absence of oxygen.

Companies use pyrolysis or gasification to turn biomass into energy. Pyrolysis and gasification are methods of high temperature “cooking” of biomass materials to produce energy, which use less oxygen than typical incineration. These techniques are an improvement over traditional incineration methods, which require higher temperatures, and emit greater CO2 emissions.

Pyrolysis operates at about 350 – 475 degrees C. The hot gasses from this process are used to drive steam generators. The waste gas from the reactor can be cooled to condense the oil content, which can be used to fuel the furnace reactor or a diesel generator. In addition, it can be refined, if needed, to be used in other ways to generate power or as a feedstock for the petrochemical industry.

And what better way to move all this biomass material than with augers. Augers perform many different jobs throughout the entire biomass to energy process. To begin, augers are used in the large biomass dryers where their unique helicoid screw design moves and mixes the biomass material in the dryers. By providing a complete and thorough mixing within the dryers, augers ensure that the biomass material is in optimum condition for the most efficient pyrolysis.

When the dried biomass is ready to be heated, augers and shaftless flight are used to carry the stored biomass feedstock, slowly and accurately feeding it into the heating reactor. The precision feeding that augers provide allow for maximum heating and processing efficiencies in the pyrolysis chamber.

Finally, augers are then used to slowly move the biomass through the pyrolysis reactor, withstanding the high temperatures required to convert biomass into gas.

“ While a simple part of the pyrolysis process, augers that are designed properly and constructed to our customers exacting specifications can make for the most efficient biomass to energy conversion,” says Brian FitzGerald, President of Falcon Industries, a leading manufacturer of custom made augers and flighting.

While pyrolysis and gasification have been around for hundreds of years, producing gas for streetlights in the 1800’s and powering motor vehicles during WWII, today the industry is starting to grow as they develop new and innovative ways of turning waste into usable power. As they improve and refine the process, augers will continue to play a key role in effectively turning waste into power.